Transformation

of Plastic Materials

In 2015 at Olitrem S.A., we invested in the transformation of plastic materials (HIPS) as a way of meeting internal needs and also responding to market needs. With a dedicated team, and a specific production area for this purpose, we do everything from the design and design of 3D parts, to their thermoforming and automatic robot cutting.

Extrusion

The extrusion process is a mechanical process of producing components continuously, where the material is forced through a matrix, thus acquiring the desired shape.

We produce and sell extruded high-impact polystyrene sheets with the customer’s specific size, color and finish, such as gloss, matte, embossed, flame retardant, among others. More information upon request.

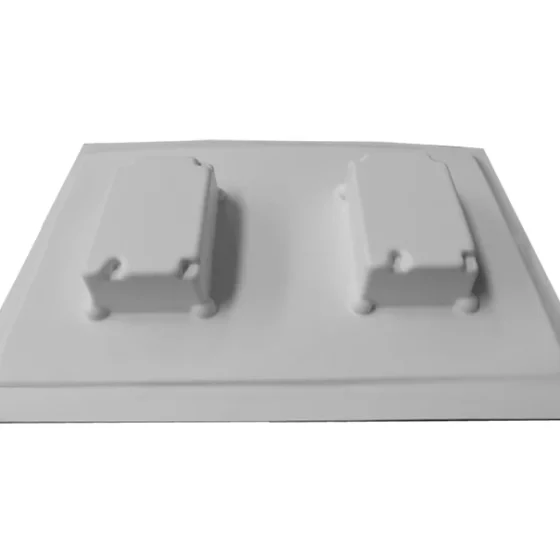

Thermoforming

For the thermoforming process, previously extruded plates are heated and shaped through heat, pressure and vacuum into the desired final configuration. After thermoforming, the final finish is guaranteed by cutting robots that guarantee the final appearance in accordance with the customer’s specification and design. More information upon request.